SKU, or "Stock Keeping Unit," is a critical concept in inventory management. It refers to the smallest distinct unit used to differentiate and manage products. Any product stored in your warehouse that has a physical difference, such as different sizing, color, or even packaging, should be treated separately in the system and assigned a unique SKU number. This helps businesses accurately track stock levels, sales, and purchasing needs.

Taking sneakers as an example, people usually refer to sneakers by their brand and model (or name) from a consumer or marketing perspective. Most customers just need to know that the "Classic Sneaker 9" is available in multiple sizes and color options.

However, it's a different story from an inventory management perspective. Without proper SKU management, every shoe box would simply say "Classic Sneaker 9." Warehouse staff would have to open each box individually to find the exact pair they need, or read through the detailed writings to know what size and color is inside the box.

Effective SKU numbers should be able to tell employees which model, size, and color the shoes are with just one glance. Warehouse staff can then easily identify stocks and even scan their barcodes into the system for tracking.

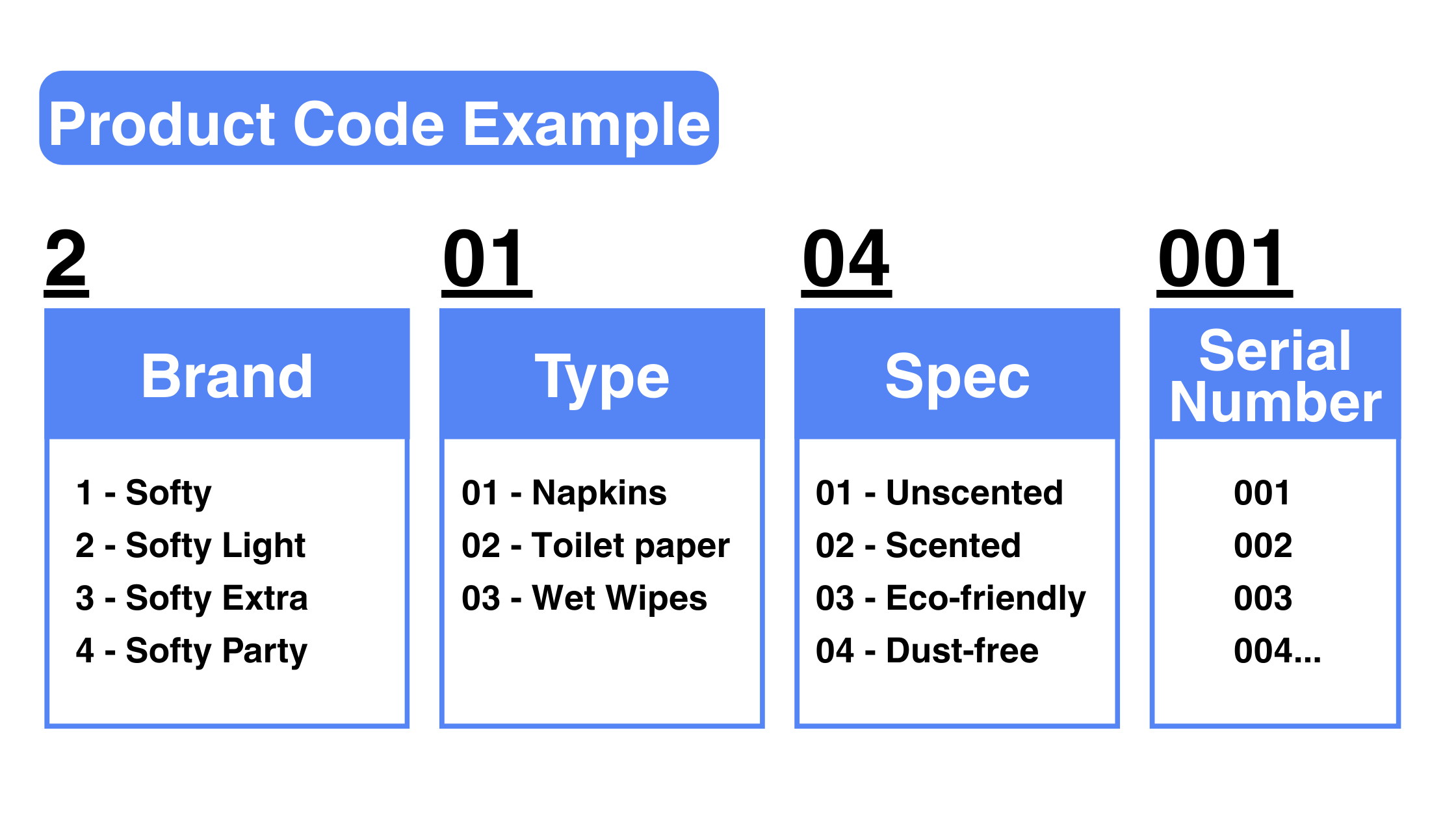

In this product coding example, employees who see the product code 20104001 would know that this is Softy Light, dust-free napkins. This can help reduce errors, increase operational efficiency, and provide a uniform, consistent method of referencing products within a company.